This is a complete guide to Sliding Angle Measurement in (2025). In this all-new guide you’ll learn all about:

● Basic Concepts & Principles

● Measurement Techniques

● The significance of Sliding Angle measurements across various industries

● Lots More

Let’s dive right in.

Understanding sliding angle is essential for optimizing surface interactions. It plays a crucial role in applications like designing anti-fouling surfaces, ensuring proper adhesion of coatings, and developing biomedical devices with specific wetting properties

Surface roughness, surface chemistry, temperature, and pressure can all alter contact angles. Additionally, liquid properties, including viscosity, density, and surface tension, play a significant role.

Understanding and manipulating these factors holds fundamental importance for processes and applications where surface interactions play a central role.

Needless to say, accurate measurement of Sliding Angles is essential. Various techniques are employed for this purpose, each with its unique advantages and disadvantages. Some of the most common methods include:

Each sliding angle measurement technique offers unique benefits and limitations, making them suitable for different applications. The Inclined Plane Method is simple and cost-effective but lacks precision. The Tilting Plate Method provides high accuracy and repeatability through automation but requires more sophisticated and expensive equipment. The Rotational Method allows for testing multiple droplets with precise control but involves a complex setup and careful calibration. Automated Optical Methods deliver extremely precise and accurate measurements with high throughput, though they demand significant investment and technical expertise. Selecting the appropriate method depends on balancing precision, cost, ease of use, and specific application needs.

Challenge: Cargo shipping companies needed to reduce fuel consumption and emissions.

Solution: Companies adopted innovative hull coatings with low surface energy and sliding angles to minimize friction with seawater. By enhancing hydrodynamic efficiency, these coatings led to significant fuel savings, reduced operational costs, and a lower carbon footprint. Droplet Lab’s portable instrument can enable accurate measurement of surface energy and sliding angles, ensuring these coatings’ effectiveness in real maritime conditions.

Challenge: Telecom companies face challenges with signal attenuation during heavy rain (rain fade) and disruptions due to ice and snow accumulation on infrastructure like antennas and satellite dishes. These issues can severely impact signal transmission reliability.

Solution: The company aimed to enhance 5G antenna performance under rainy conditions by developing superhydrophobic coatings. Through rigorous experiments with different coatings, they optimized contact angles to design surfaces with high water repellency. This innovation significantly reduced rain attenuation by preventing water droplets from interfering with signal transmission. As a result, the antennas maintained strong signal strengths even during heavy rain.

Moreover, in cold regions prone to ice and snow buildup on satellite dishes, the company conducted tests to identify superhydrophobic materials with large contact angles and low sliding angles. These materials effectively minimized ice adhesion, ensuring uninterrupted signal reception. By reducing the accumulation of ice on the dishes, they enhanced operational reliability and maintained consistent signal transmission in extreme weather conditions.

Details: Even minor contaminants like dust, oils, or residues can significantly alter sliding angle readings. These contaminants can change the surface properties, leading to inconsistent and inaccurate measurements.

Solution: Ensure thorough cleaning of surfaces and perform measurements in controlled environments to minimize contamination.

Details: Variations in surface roughness can affect how droplets interact with the surface, impacting the sliding angle. Rough surfaces can create inconsistencies due to uneven wetting and increased friction.

Solution: Use smooth, uniform surfaces for accurate measurements. Apply models that account for surface roughness effects if rough surfaces are unavoidable.

Details: Temperature changes can influence the viscosity and surface tension of the liquid, affecting the sliding angle. Consistent temperature is crucial for reliable measurements.

Solution: Maintain a controlled temperature environment during experiments and calibrate instruments to account for temperature variations.

Details: Manual tilting methods can introduce human error and inconsistencies in measurements. Variations in the speed of tilting and judgment of the sliding point can affect accuracy.

Solution: Use automated systems like the tilting plate method to ensure consistent and precise angle adjustments, reducing human error.

Details: The volume and shape of the droplet can affect the sliding angle. Larger droplets may slide at different angles compared to smaller ones due to changes in contact area and weight.

Solution: Standardize droplet volume and ensure consistent droplet shape during measurements to maintain accuracy.

Details: Different surface treatments (e.g., hydrophobic or hydrophilic coatings) can alter the sliding angle significantly. These treatments can wear off over time, affecting repeatability.

Solution: Ensure surface treatments are applied uniformly and maintained consistently. Regularly check and reapply treatments if necessary.

Details: Environmental factors such as humidity, airflow, and vibrations can impact sliding angle measurements. These factors can cause droplets to behave unpredictably.

Solution: Conduct measurements in a controlled environment with minimal external disturbances to ensure accurate results.

Details: Instruments used for measuring sliding angles need precise calibration. Misalignment or improper calibration can introduce significant errors.

Solution: Regularly calibrate instruments according to manufacturer guidelines and perform routine checks to ensure accuracy.

Details: Interpreting sliding angle data often involves complex calculations and models. Misapplication of these models can lead to inaccurate results.

Solution: Use software tools for data analysis and ensure a thorough understanding of the theoretical models applied.

By addressing these challenges systematically, researchers can achieve more accurate and reliable sliding angle measurements, leading to better material characterization and application.

Description: Clean both the sample surfaces and the measurement apparatus thoroughly to remove any contaminants like dust, oils, or residues.

Method: Use solvents like ethanol or acetone followed by drying with nitrogen gas or clean air.

Description: Maintain a consistent environment in terms of temperature, humidity, and airflow.

Method: Use a controlled environment chamber if possible. Monitor and record environmental conditions during each measurement.

Description: Ensure the surface of the sample is smooth and uniform to minimize the effects of surface roughness on the measurements.

Method: Use polishing or other surface preparation techniques. Verify uniformity with a microscope or other surface analysis tools.

Description: Use droplets of consistent volume and shape for each measurement to ensure uniform contact area and weight.

Method: Use a precise syringe or micro-pipette to dispense droplets. Calibrate the droplet size regularly.

Description: Use automated tilting systems to achieve precise and consistent angle adjustments.

Method: Employ motorized tilting stages that can be controlled and monitored electronically to reduce human error

Description: Perform regular calibration of all measurement instruments to ensure accuracy.

Method: Follow manufacturer guidelines for calibration. Use standard reference materials to verify instrument performance.

Description: Adhere to a standardized procedure for every measurement to ensure consistency.

Method: Develop a detailed protocol that includes step-by-step instructions and ensure all operators are trained to follow it precisely.

Description: Ensure that the speed at which droplets are deposited onto the surface is consistent to avoid variations in initial contact behavior.

Method: Use automated droplet deposition systems if possible. If manual, train operators to maintain a consistent deposition speed.

Description: Record all relevant variables and conditions for each measurement, including droplet size, surface preparation method, environmental conditions, and equipment settings.

Method: Use a standardized data recording sheet or digital logging system.

Description: Perform multiple measurements for each condition to ensure reliability and reproducibility.

Method: Conduct at least three repetitions for each sample and average the results. Report the standard deviation to assess variability.

Description: Continuously review and refine measurement procedures to incorporate improvements and address any issues.

Method: Conduct periodic audits of the measurement process and gather feedback from operators.

Droplet Lab’s smartphone-based approach offers comparable Sliding Angle measurement accuracy as traditional instruments, along with simplicity, compactness, and portability. This innovative method overcomes the challenges posed by smartphone optical zoom by utilizing an advanced image analysis algorithm.

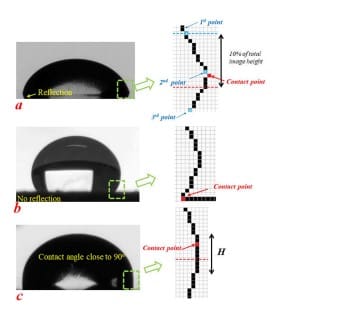

The smartphone instrument uses both Young-Laplace and polynomial fitting methods to calculate contact angles. However, it employs Otsu’s algorithm to detect the drop profile from digitally zoomed images, ensuring precise contact point identification. For drops with reflections, the algorithm detects changes in the slope of the drop profile to locate contact points. Without reflections, it identifies the point where the slope becomes zero.

Schematic for principle of contact point detection system: (a) an image of a drop with reflection, (b) an image of a drop without reflection, and (c) a drop with a contact angle close to 90 . The right column shows digitally detected profiles (the dashed box shows the estimated area to guide the eyes).

Description: Explore surfaces with extreme wetting properties, characterized by very high or very low sliding angles. Superhydrophobic surfaces cause water droplets to roll off easily, mimicking the lotus leaf effect, while superhydrophilic surfaces allow water to spread entirely.

Applications: These surfaces are critical in developing self-cleaning materials, anti-fouling coatings, and water-repellent textiles.

Description: Study the behavior of droplets under dynamic conditions, such as varying tilting speeds and accelerations. This involves observing how droplets transition from sticking to sliding and understanding the impact of inertia and surface forces.

Applications: Important for applications in printing technologies, coating processes, and understanding droplet behavior in microfluidic devices.

Description: Investigate how chemical treatments (e.g., hydrophobic coatings) and physical modifications (e.g., micro/nanostructuring) alter sliding angles. This includes studying the effects of surface energy modifications and roughness.

Applications: Useful in developing advanced materials for biomedical implants, anti-icing surfaces, and high-performance coatings.

Description: Examine how external factors such as humidity, temperature, and atmospheric pressure affect sliding angles. This involves understanding the interaction between environmental conditions and surface properties.

Applications: Critical for outdoor applications of coatings and materials, such as in automotive, aerospace, and construction industries.

Description: Analyze how interfacial rheological properties (e.g., viscoelasticity) and droplet deformation affect the sliding angle. This includes studying how droplets deform under the influence of surface forces and gravitational pull.

Applications: Relevant for formulations in pharmaceuticals, food science, and understanding the behavior of complex fluids on surfaces.

Description: Utilize high-speed cameras and advanced computational models to capture and simulate the sliding behavior of droplets in real-time. This involves detailed analysis of the contact line dynamics and droplet motion.

Applications: Enhances the precision of sliding angle measurements and provides deeper insights into droplet-surface interactions, benefiting research in fluid dynamics and surface engineering.

Description: Develop techniques for measuring sliding angles at the nano and micro-scale, where surface forces dominate over gravitational forces. This includes using atomic force microscopy (AFM) and other high-resolution tools.

Applications: Crucial for designing and testing surfaces in nanotechnology, microelectronics, and biomedical devices where precise control of wetting properties is essential.

Sliding angle measurement is a crucial aspect of surface science, providing insights into wettability, adhesion, and material interactions. Understanding and accurately measuring sliding angles can drive advancements in various industries, from coatings and biomedical devices to nanotechnology and microfluidics. This guide has explored fundamental concepts, detailed measurement techniques, and advanced topics, equipping researchers and professionals with the knowledge to optimize their surface engineering efforts. By addressing challenges and employing precise methods, we can enhance material performance and innovate solutions for complex surface-related problems.

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.