Contact angle measurement is a cornerstone technique in surface science, providing insights into wettability, adhesion, and surface energy. However, achieving reproducible measurements is critical for meaningful interpretation and application.

Reproducibility ensures reliability across different laboratories and experimental conditions. Challenges in reproducibility often arise from variations in surface preparation, droplet size, and environmental factors. Non-reproducible data can lead to incorrect conclusions about a material’s surface properties and undermine the credibility of the research.

To have an in-depth understanding of Contact-Angle measurements and their applications please refer to our Contact Angle Measurement Definitive Guide. Here, we outline 10 essential steps to help you achieve reproducible contact angle measurements, incorporating findings from literature and practical insights.

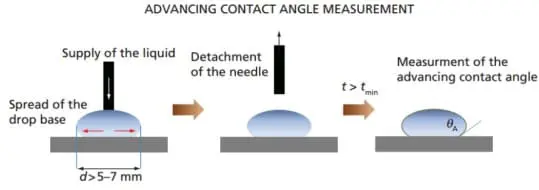

Determined by slowly adding liquid to the droplet as the liquid front advances over a dry surface.

Measured by gradually removing liquid as the liquid front recedes from a wetted surface.

Contact angle hysteresis is the difference between advancing and receding angles. It can indicate surface roughness or chemical heterogeneity.

Learn how you can perform Advancing and Receding contact Angle measurements:

Surface preparation significantly affects contact angle reproducibility. Surface imperfections, such as roughness or chemical heterogeneity, can cause significant contact angle hysteresis. Employ larger droplets to average out local variations. For rough surfaces, consider surface modification techniques to achieve smoother profiles.

Follow these guidelines:

Environmental factors like temperature, humidity, and vibrations can significantly impact measurements. Place the setup in an environment free from air currents, temperature fluctuations, and contaminant exposure. A closed chamber or hood can provide additional isolation, especially for sensitive experiments.

Some best practices include:

Accurate calibration ensures reliable data. Regular calibration of contact angle instruments is essential for accuracy. Calibration can be performed using standard reference materials with known contact angles. Advanced setups may also include self-check mechanisms to validate system performance. Regularly verify:

Selecting a liquid with well-characterized properties enhances reproducibility:

During droplet deposition, ensure smooth and controlled delivery to minimize oscillations or shape distortions. A syringe with a hydrophobic needle tip prevents liquid climbing on the needle surface, reducing inconsistencies.

Proper droplet size and placement are crucial:

Manual measurements are prone to operator bias. If manual methods are used, thorough training and adherence to protocols are essential.

Modern contact angle instruments employ image analysis to calculate angles by fitting the droplet profile to the Young-Laplace equation. This method reduces human error and enhances precision. Ensure software settings are optimized for droplet size, lens magnification, and lighting conditions. Automated systems with image analysis software can enhance accuracy and consistency.

Leverage modern tools for precision:

Perform measurements at multiple points to account for surface variability:

Gage Repeatability and Reproducibility (GR&R)

Conduct GR&R studies to evaluate the precision and reliability of both the measurement instrument and the operator. GR&R studies involve:

Transparency in reporting enables reproducibility by others:

Detailed Protocols: Include information on surface preparation, liquid properties, and environmental conditions.

Example Workflow

| Step | Description |

|---|---|

| 1 | Prepare substrate: Clean, polish, and store in a controlled environment. |

| 2 | Calibrate the instrument using a standard reference. |

| 3 | Deposit a droplet using a clean syringe and measure the static contact angle. |

| 4 | Add liquid to measure the advancing angle. |

| 5 | Remove liquid to measure the receding angle. |

| 6 | Repeat measurements at multiple locations on the sample for statistical validation. |

Photographs or Diagrams: Show the experimental setup to eliminate ambiguity

Contact angle hysteresis can provide insights into material properties:

Consider investing in Droplet Lab’s Smartphone-based Goniometer that offers precise drop generation using Hamilton Syringes in both manual and Automatic models.

Image Analysis Algorithms: Utilize software like Young-Laplace fitting to analyze droplet profiles accurately.

Droplet Lab’s Goniometer uses Young-Laplace equation and integrates Custom-Built machine learning model trained on 24,000+ images offers consistent, effortless measurements.

.

Controlled Humidity Chambers: For ultra-precise measurements, advanced environmental chambers can control temperature, humidity, and atmospheric composition. These chambers are especially useful for sensitive materials prone to rapid oxidation or contamination.

High-Purity Liquids: Ensure consistency in droplet properties.

Macroscopic Contact Angles: Defined as a boundary condition for stress equations governing liquid-vapor interfaces. They are essential for predicting the shapes of fluid bodies and depend on precise measurement techniques.

Microscopic Contact Angles: Derived from molecular forces at the contact line and linked to interfacial tensions through the Young-Dupre equation.

Reproducible contact angle measurements are essential for reliable surface characterization. Achieving reproducible contact angle measurements requires a combination of meticulous preparation, precise techniques, and advanced tools. By following these 10 steps, researchers and professionals can ensure reliable, accurate, and meaningful results, contributing to advancements in surface science and material characterization.

Leveraging advanced techniques such as image analysis and GR&R studies further enhances confidence in results. With careful attention to detail, contact angle measurements can provide valuable insights into material properties, aiding in innovation across various industries.

For more insights and guides, visit our Surface Science Knowledge Hub.

References

1. Drelich, J. (2013). Guidelines to measurements of reproducible contact angles using a sessile-drop technique. Surface Innovations, 1(SI4), 248-254. DOI: 10.1680/si.13.00010.

2. Brighton Science. (2022). Gage Repeatability and Reproducibility of the Surface Analyst. Available at: Brighton Science Website.

3. Decker, E. L., et al. (1999). Physics of contact angle measurement. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 156,

177-189. DOI: 10.1016/S0927-7757(99)00069-2.

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.