Reviewed: 28

This is a practical guide to Surface Science for researchers working in the Aviation & Space Industry.

In this all-new guide you’ll learn all about:

Let’s dive right in.

The aviation industry and space applications heavily rely on surface science. To meet the demanding conditions of these fields, which involve extreme environments and long-term performance, surfaces and coatings are crucial. In aviation, the characteristics of aircraft parts like turbine blades, airfoils, and engine components significantly impact their performance and lifespan. To enhance their resistance to wear, corrosion, high temperatures, and icing, surface coatings and treatments are applied.

This eventually improves:

We use the important surface properties below to understand the behavior of Aviation & Space products and improve their quality.

Young – Laplace Method

Polynomial Method

Dynamic Contact Angle

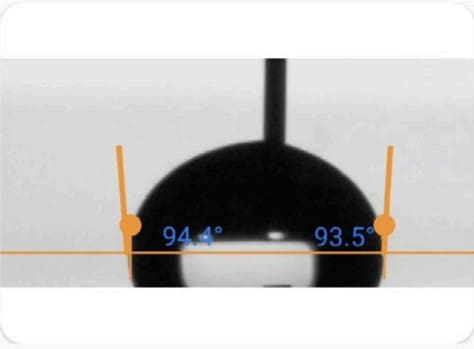

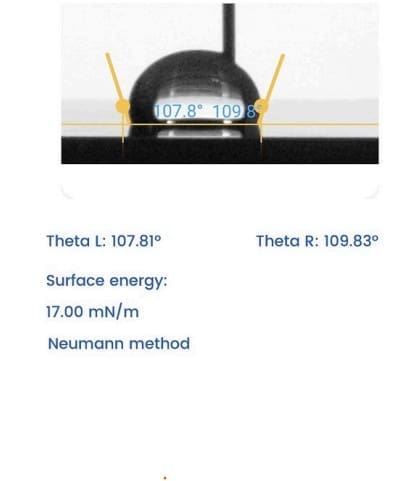

Ideally, when we place a drop on a solid surface, a unique angle exists between the liquid and the solid surface. We can calculate the value of this ideal contact angle (the so-called Young’s contact angle) using Young’s equation. In practice, due to surface geometry, roughness, heterogeneity, contamination, and deformation, the contact angle value on a surface is not necessarily unique but falls within a range. We call this range’s upper and lower limits the advancing contact angle and the receding contact angle, respectively. The values of advancing and receding contact angles for a solid surface are also very sensitive. They can be affected by many parameters, such as temperature, humidity, homogeneity, and minute contamination of the surface and liquid. For example, the advancing and receding contact angles of a surface can differ at different locations.

Practical surfaces and coatings naturally show contact angle hysteresis, indicating a range of equilibrium values. When we measure static contact angles, we get a single value within this range. Solely relying on static measurements poses problems, like poor repeatability and incomplete surface assessment regarding adhesion, cleanliness, roughness, and homogeneity.

In practical applications, we need to understand a surface’s liquid spreading ease (advancing angle) and removal ease (receding angle), such as in painting and cleaning. Measuring advancing and receding angles offers a holistic view of liquid-solid interaction, unlike static measurements, which yield an arbitrary value within the range.

This insight is crucial for real-world surfaces with variations, roughness, and dynamics, aiding industries like cosmetics, materials science, and biotechnology in designing effective surfaces and optimizing processes.

Learn how Contact Angle measurement is done on our Tensiometer

For a more complete understanding of Contact Angle measurement, read our Contact Angle measurement: The Definitive Guide

This property measures the force that acts on the surface of a liquid, aiming to minimize its surface area.

Dynamic Surface Tension

Dynamic surface tension differs from static surface tension, which refers to the surface energy per unit area (or force acting per unit length along the edge of a liquid surface).

Static surface tension characterizes the equilibrium state of the liquid interface, while dynamic surface tension accounts for the kinetics of changes at the interface. These changes could involve the presence of surfactants, additives, or variations in temperature, pressure, and composition at the interface.

Dynamic surface tension is essential for processes that involve rapid changes at the liquid-gas or liquid-liquid interface, such as droplet and bubble formation or coalescence (change of surface area), behavior of foams, and drying of paints (change of composition, e.g., evaporation of solvent). We measure it by analyzing the shape of a hanging droplet over time.

Dynamic surface tension applies to various industries, including cosmetics, coatings, pharmaceuticals, paint, food and beverage, and industrial processes, where understanding and controlling the behavior of liquid interfaces is essential for product quality and process efficiency.

Learn how Surface Tension measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Tension measurement: The Definitive Guide

Learn how Surface Energy measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Energy measurement: The Definitive Guide

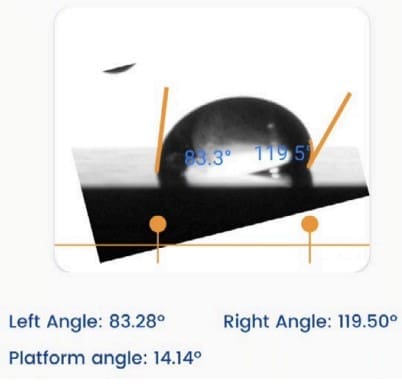

The sliding angle measures the angle at which a liquid film slides over a solid surface. It is commonly employed to assess the slip resistance of a surface.

Learn how Sliding Angle measurement is done on our Tensiometer

For a more complete understanding of Sliding Angle measurement, read our Sliding Angle Measurement: The Definitive Guide

Within the Aviation & Space industry, several case studies exemplify the advantages of conducting surface property measurements.

Think about it: Airplane paint isn’t just for looks. Weighing in at a hefty 500 kg, it significantly impacts the aircraft’s fuel consumption.

But it goes beyond weight management. Paint acts as the aircraft’s first line of defense against often-overlooked enemies like corrosive rain and harsh UV radiation.

Therefore, aircraft paint needs to meet several crucial demands: high surface energy, excellent wettability, and minimal weight. At Droplet Lab, our tensiometer helps strike this delicate balance, resulting in aircraft paints that are both durable and fuel-efficient.

Space provides a radically different setting than Earth, affecting everything it touches, including cell culture systems. The unique thermodynamics and mechanics of space make standard ground-based cell culture systems unpredictable. Microgravity and the absence of buoyancy-driven convection cause deviations in behavior. To address these changes, modern research focuses on understanding the dynamics of contact angles and surface properties of cell culture media. By providing researchers with the right tools, such as our tensiometer, we help them optimize space-bound cell culture systems and ensure their findings are accurate and actionable.

If you are interested in implementing these or any other applications, please contact us.

In an industry where precision reigns supreme, where do Aviation & Space manufacturers turn to ensure their products can survive scrutiny? The answer lies in standards and guidelines: the compass that guides cosmetics manufacturers through the complex maze of quality and performance.

This test method is rapid, nondestructive, and may be used for the control and evaluation of processes for the removal of hydrophobic contaminants.

The test is to provide a controlled accelerated corrosive environment to evaluate the relative corrosion resistance of the coating, substrate, or part itself.

This applies to water and is applicable only to potable water and high-purity demineralized or deionized water, used for cooling and servicing in space systems.

We hope this guide showed you how to apply surface science in cosmetics industry.

Now we’d like to turn it over to you:

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.