Reviewed: 28

This is a practical guide to Surface Science for researchers working in the Biotechnology Industry.

In this all-new guide you’ll learn all about:

Let’s dive right in.

In the biotech industry, we measure contact angle, surface energy, and surface tension to evaluate the wettability and surface properties of materials. These measurements significantly impact various applications, including drug delivery systems, biomaterials, tissue engineering, and diagnostic devices. By understanding the interfacial behavior and surface characteristics, we can optimize the performance, reliability, and biocompatibility of biotech products.

We use the important surface properties below to understand the behavior of Biotechnology products and improve their quality.

Young – Laplace Method

Polynomial Method

Dynamic Contact Angle

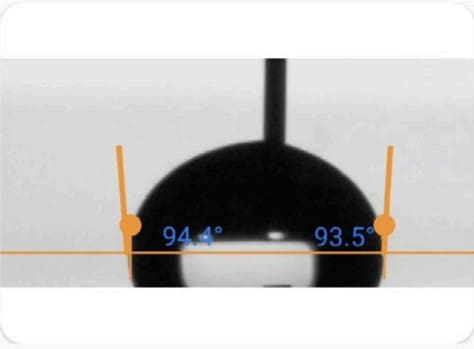

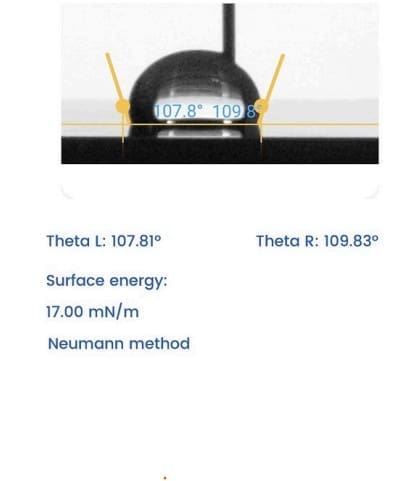

Ideally, when we place a drop on a solid surface, a unique angle exists between the liquid and the solid surface. We can calculate the value of this ideal contact angle (the so-called Young’s contact angle) using Young’s equation. In practice, due to surface geometry, roughness, heterogeneity, contamination, and deformation, the contact angle value on a surface is not necessarily unique but falls within a range. We call this range’s upper and lower limits the advancing contact angle and the receding contact angle, respectively. The values of advancing and receding contact angles for a solid surface are also very sensitive. They can be affected by many parameters, such as temperature, humidity, homogeneity, and minute contamination of the surface and liquid. For example, the advancing and receding contact angles of a surface can differ at different locations.

Practical surfaces and coatings naturally show contact angle hysteresis, indicating a range of equilibrium values. When we measure static contact angles, we get a single value within this range. Solely relying on static measurements poses problems, like poor repeatability and incomplete surface assessment regarding adhesion, cleanliness, roughness, and homogeneity.

In practical applications, we need to understand a surface’s liquid spreading ease (advancing angle) and removal ease (receding angle), such as in painting and cleaning. Measuring advancing and receding angles offers a holistic view of liquid-solid interaction, unlike static measurements, which yield an arbitrary value within the range.

This insight is crucial for real-world surfaces with variations, roughness, and dynamics, aiding industries like cosmetics, materials science, and biotechnology in designing effective surfaces and optimizing processes.

Learn how Contact Angle measurement is done on our Tensiometer

For a more complete understanding of Contact Angle measurement, read our Contact Angle measurement: The Definitive Guide

This property measures the force that acts on the surface of a liquid, aiming to minimize its surface area.

Dynamic Surface Tension

Dynamic surface tension differs from static surface tension, which refers to the surface energy per unit area (or force acting per unit length along the edge of a liquid surface).

Static surface tension characterizes the equilibrium state of the liquid interface, while dynamic surface tension accounts for the kinetics of changes at the interface. These changes could involve the presence of surfactants, additives, or variations in temperature, pressure, and composition at the interface.

Dynamic surface tension is essential for processes that involve rapid changes at the liquid-gas or liquid-liquid interface, such as droplet and bubble formation or coalescence (change of surface area), behavior of foams, and drying of paints (change of composition, e.g., evaporation of solvent). We measure it by analyzing the shape of a hanging droplet over time.

Dynamic surface tension applies to various industries, including cosmetics, coatings, pharmaceuticals, paint, food and beverage, and industrial processes, where understanding and controlling the behavior of liquid interfaces is essential for product quality and process efficiency.

Learn how Surface Tension measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Tension measurement: The Definitive Guide

Learn how Surface Energy measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Energy measurement: The Definitive Guide

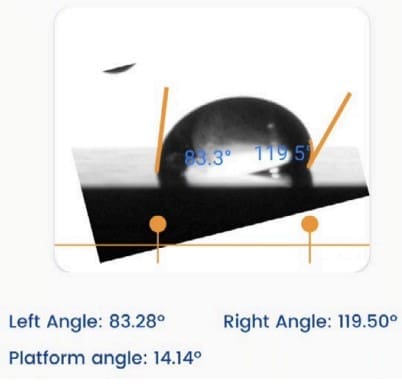

The sliding angle measures the angle at which a liquid film slides over a solid surface. It is commonly employed to assess the slip resistance of a surface.

Learn how Sliding Angle measurement is done on our Tensiometer

For a more complete understanding of Sliding Angle measurement, read our Sliding Angle Measurement: The Definitive Guide

Within the Biotechnology industry, several case studies exemplify the advantages of conducting surface property measurements.

Glycolipid biosurfactants from yeast represent a sustainable innovation in chemical production. Various industries, from food to cosmetics, rely on these surfactants. Crucially, dissolved oxygen plays a key role in their synthesis. It provides microorganisms with sufficient oxygen and creates the ideal environment for proper growth. Therefore, membranes that monitor dissolved oxygen levels must achieve the right balance: hydrophobic enough to repel cell debris but not so hydrophobic that they trap air bubbles. Researchers use tools like the tensiometer developed by Droplet Lab to assess the surface properties of these membranes and the fermentation solution, ensuring a seamless and precise production process.

Medical implants, scaffolds, and biosensors are transforming our lives and becoming everyday reality. Understanding how different biomaterial surfaces interact with water, either attracting (hydrophilic) or repelling (hydrophobic) it, is crucial. This knowledge directly impacts everything from cell adhesion to tissue regeneration. For example, by carefully adjusting the surface energy and roughness of a substrate, we can significantly enhance cell growth. Surface tension plays a key role in fabricating hybrid materials. We can combine 3D printed polymers with cell-laden hydrogels to create fully biocompatible, 3D structures of living tissues. This innovative approach utilizes surface-wetting forces to suspend liquid films across the openings of a mesh, which can then be converted into a solid coating or hydrogel.

It’s easy to dismiss nanoparticles as insignificant due to their small size, but looks can be deceiving. Despite their tiny size, they’re revolutionizing the biotech industry with their remarkable versatility. Their large surface area to volume ratio, coupled with adjustable surface chemistry, makes them ideal for drug delivery systems. Take glaucoma treatment, for example. Both the medication itself and its delivery method play crucial roles in its effectiveness. By analyzing contact angles, researchers can precisely control how drug-loaded nanoparticles interact with the eye’s surface. This leads to optimized formulations that not only improve patient outcomes but also ensure sustained and efficient drug delivery.

Modern bioprocesses offer fascinating journeys, transforming raw materials into potentially life-saving drugs or vital enzymes. However, the initial stages often present inclusion bodies or crystals. These bioprocesses create a complex liquid phase, a melting pot of diverse bioparticles ranging from cell debris and whole cells to particulate biocatalysts and by-products. Separating these valuable entities from the surrounding other particles is no easy feat, with the contact angle of each bioparticle playing a crucial role in this purification process.

Surface properties take center stage here, as a particle’s surface dictates its interactions with its environment. This is where our tools come into play, providing researchers with the detailed insights needed to optimize the purification process. For example, drying and re-dispersing these particles present significant challenges. Without understanding the capillary forces at play – forces directly influenced by surface tension – particles can easily aggregate or films can crack. By providing precise measurements, we empower researchers to avoid these pitfalls and achieve the highest possible product quality.

If you are interested in implementing these or any other applications, please contact us.

In an industry where precision reigns supreme, where do Biotechnology manufacturers turn to ensure their products can survive scrutiny? The answer lies in standards and guidelines: the compass that guides cosmetics manufacturers through the complex maze of quality and performance.

This standard is applicable to measure the critical surface tension of substrates, primers, and other coatings. The measurements are based on the observation of wetting and dewetting of different liquids applied to the targeted surface.

It provides a procedure for the characterization of the wettability of surfaces by applying contact angle measurements.

Determination of interfacial tension — Drop volume method. It provides a method to measure the interfacial tension between two liquids. Interfacial tension is essential for formulating stable emulsions and suspensions of drugs and other bioactive compounds, as well as affecting cell culture processes, especially in bioreactor systems.

The purpose of this standard is to establish broad criteria that ensure the quality of measurement processes, resulting in precise and reliable readings. It also provides general guidelines for the appropriate training of personnel involved in measurements. It should be noted that this standard does not specify specific acceptable tolerances. Instead, its primary focus is to assist laboratories in developing and implementing quality processes by emphasizing critical factors necessary for accurate measurements and promoting effective training practices for personnel involved in taking measurements.

We hope this guide showed you how to apply surface science in cosmetics industry.

Now we’d like to turn it over to you:

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.