Reviewed: 28

This is a practical guide to Surface Science for researchers working in the Construction Industry.

In this all-new guide you’ll learn all about:

Let’s dive right in.

Concrete is the most widely used material in the global construction industry. It is cost-effective, offers high compressive strength, is durable, has a relatively simple production process, and requires minimal maintenance. Despite these advantages, concrete has a hydrophilic, porous structure that can pose challenges during construction. One major issue is the corrosion of steel reinforcement due to concrete’s water absorption, which reduces the lifespan of concrete structures. Additionally, there is a growing demand for intelligent, resilient, and sustainable buildings and infrastructures that focus on reducing greenhouse gas emissions. To meet these demands, new concrete materials such as low carbon footprint cement, self-compacting concrete, self-healing and self-sensing concrete, and superhydrophobic cementitious materials with self-cleaning capabilities have been developed. Modifying surface properties plays a crucial role in addressing the challenges of traditional concrete and in creating this new class of advanced materials.

We use the important surface properties below to understand the behavior of Construction products and improve their quality.

Young – Laplace Method

Polynomial Method

Dynamic Contact Angle

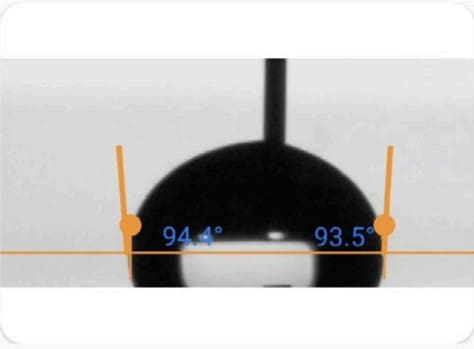

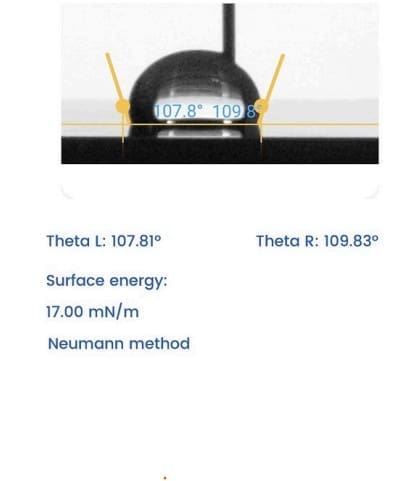

Ideally, when we place a drop on a solid surface, a unique angle exists between the liquid and the solid surface. We can calculate the value of this ideal contact angle (the so-called Young’s contact angle) using Young’s equation. In practice, due to surface geometry, roughness, heterogeneity, contamination, and deformation, the contact angle value on a surface is not necessarily unique but falls within a range. We call this range’s upper and lower limits the advancing contact angle and the receding contact angle, respectively. The values of advancing and receding contact angles for a solid surface are also very sensitive. They can be affected by many parameters, such as temperature, humidity, homogeneity, and minute contamination of the surface and liquid. For example, the advancing and receding contact angles of a surface can differ at different locations.

Practical surfaces and coatings naturally show contact angle hysteresis, indicating a range of equilibrium values. When we measure static contact angles, we get a single value within this range. Solely relying on static measurements poses problems, like poor repeatability and incomplete surface assessment regarding adhesion, cleanliness, roughness, and homogeneity.

In practical applications, we need to understand a surface’s liquid spreading ease (advancing angle) and removal ease (receding angle), such as in painting and cleaning. Measuring advancing and receding angles offers a holistic view of liquid-solid interaction, unlike static measurements, which yield an arbitrary value within the range.

This insight is crucial for real-world surfaces with variations, roughness, and dynamics, aiding industries like cosmetics, materials science, and biotechnology in designing effective surfaces and optimizing processes.

Learn how Contact Angle measurement is done on our Tensiometer

For a more complete understanding of Contact Angle measurement, read our Contact Angle measurement: The Definitive Guide

This property measures the force that acts on the surface of a liquid, aiming to minimize its surface area.

Dynamic Surface Tension

Dynamic surface tension differs from static surface tension, which refers to the surface energy per unit area (or force acting per unit length along the edge of a liquid surface).

Static surface tension characterizes the equilibrium state of the liquid interface, while dynamic surface tension accounts for the kinetics of changes at the interface. These changes could involve the presence of surfactants, additives, or variations in temperature, pressure, and composition at the interface.

Dynamic surface tension is essential for processes that involve rapid changes at the liquid-gas or liquid-liquid interface, such as droplet and bubble formation or coalescence (change of surface area), behavior of foams, and drying of paints (change of composition, e.g., evaporation of solvent). We measure it by analyzing the shape of a hanging droplet over time.

Dynamic surface tension applies to various industries, including cosmetics, coatings, pharmaceuticals, paint, food and beverage, and industrial processes, where understanding and controlling the behavior of liquid interfaces is essential for product quality and process efficiency.

Learn how Surface Tension measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Tension measurement: The Definitive Guide

Learn how Surface Energy measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Energy measurement: The Definitive Guide

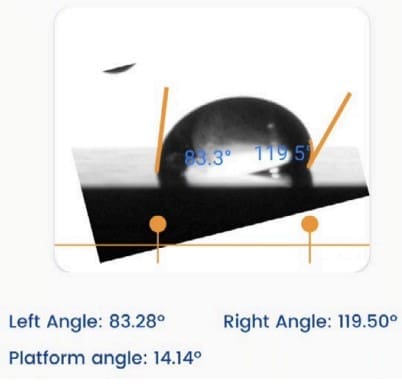

The sliding angle measures the angle at which a liquid film slides over a solid surface. It is commonly employed to assess the slip resistance of a surface.

Learn how Sliding Angle measurement is done on our Tensiometer

For a more complete understanding of Sliding Angle measurement, read our Sliding Angle Measurement: The Definitive Guide

Within the Construction industry, several case studies exemplify the advantages of conducting surface property measurements.

Challenge: Dust and pollution accumulated on the solar panels of a commercial building, reducing their energy generation efficiency.

Solution: Applying a hydrophobic and oleophobic coating to the solar panels increased the contact angle, causing rainwater to bead up and carry away dust and pollutants. This self-cleaning effect improved energy generation efficiency and reduced maintenance costs.

Challenge: Water leakage in an underground parking structure was causing vehicle damage and structural deterioration.

Solution: A waterproofing membrane with low surface tension was applied to the concrete surfaces. This membrane provided effective water repellency, preventing water infiltration and preserving the integrity of the parking structure while protecting the vehicles.

Challenge: Slippery pedestrian walkways in a shopping mall led to slip and fall accidents during rainy weather.

Solution: The mall management installed textured, slip-resistant tiles with superhydrophobic surfaces. These tiles, characterized by a water static contact angle above 150° and a sliding angle below 10°, provided better traction even when wet, significantly reducing slip and fall incidents. This increased safety for shoppers and employees and decreased the mall’s liability for accidents.

Challenge: Engineers faced adhesion problems between the steel and concrete components in a steel-concrete composite structure due to incompatible surface energies.

Solution: The engineering team applied a bonding agent to the steel beams to modify their surface energy. This agent enhanced compatibility between the steel and concrete, resulting in a robust bond. The composite structure exhibited improved load-bearing capacity and durability, ensuring the building’s safety and longevity.

Challenge: An automotive assembly plant experienced paint adhesion problems on metal components, leading to defects and reduced vehicle durability.

Solution: The engineering team improved paint adhesion by selecting a suitable metal pretreatment process. They tested various processes and chose plasma cleaning, which had the lowest surface tension. This solution ensured a durable, long-lasting finish on the vehicles.

If you are interested in implementing these or any other applications, please contact us.

In an industry where precision reigns supreme, where do Construction manufacturers turn to ensure their products can survive scrutiny? The answer lies in standards and guidelines: the compass that guides cosmetics manufacturers through the complex maze of quality and performance.

This standard provides a method for determining the tensile strength of concrete near the prepared surface, which can be used as an indicator of the adequacy of surface preparation before applying a repair or an overlay material. This method is useful to evaluate the bond strength to the substrate or the tensile strength of the overlay or substrate (whichever is weaker) and the adhesive strength of bonding agents.

This standard provides terms and classifications, characteristics, and marking requirements for ceramic tiles of the best commercial quality (first quality) [9]. ISO prescribes documents that constitute this standard. The documents that are specifically related to surface property are

ISO 10545-2, Ceramic tiles — Part 2: Determination of dimensions and surface quality

ISO 10545-7, Ceramic tiles — Part 7: Determination of resistance to surface abrasion for glazed tiles

ISO 27448:2009(en) Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for self-cleaning performance of semiconducting photocatalytic materials — Measurement of water contact angle

This standard is related to fine ceramics material. It provides a test method to determine the self-cleaning performance of materials that contain a photocatalyst or have photocatalytic films on the surface. These materials are usually made from semiconducting metal oxides such as titanium dioxide. This method can be used to measure the water contact angle under illumination with ultraviolet light, which is one of the indices influencing the self-cleaning performance of photocatalytic materials

We hope this guide showed you how to apply surface science in cosmetics industry.

Now we’d like to turn it over to you:

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.