Reviewed: 28

This is a practical guide to Surface Science for researchers working in the Cosmetics Industry.

In this all-new guide you’ll learn all about:

Let’s dive right in.

Understanding how cosmetics interact with the skin relies on the surface tension of liquids and the contact angle, that a liquid droplet generates when it meets a solid surface. These characteristics directly impact the product performance and user experience by influencing how they spread, adhere, and enter the skin.

Cosmetic formulation combines art and science to create products that embellish and enhance a person’s natural attractiveness. Striking the ideal balance between practicality and beauty can be challenging. Cosmetic formulators ensure products withstand everyday use while maintaining their aesthetic appeal by prioritizing

We use the important surface properties below to understand the behavior of Cosmetics products and improve their quality.

Young – Laplace Method

Polynomial Method

Dynamic Contact Angle

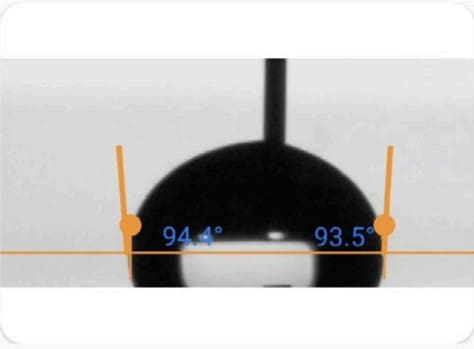

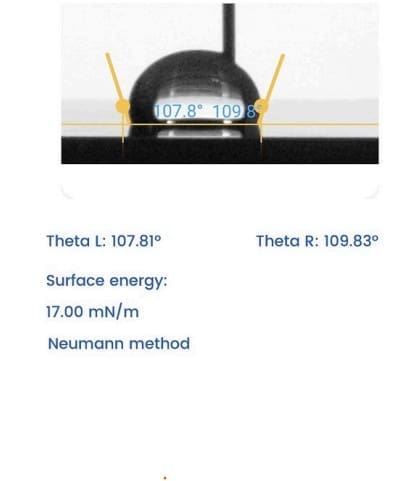

Ideally, when we place a drop on a solid surface, a unique angle exists between the liquid and the solid surface. We can calculate the value of this ideal contact angle (the so-called Young’s contact angle) using Young’s equation. In practice, due to surface geometry, roughness, heterogeneity, contamination, and deformation, the contact angle value on a surface is not necessarily unique but falls within a range. We call this range’s upper and lower limits the advancing contact angle and the receding contact angle, respectively. The values of advancing and receding contact angles for a solid surface are also very sensitive. They can be affected by many parameters, such as temperature, humidity, homogeneity, and minute contamination of the surface and liquid. For example, the advancing and receding contact angles of a surface can differ at different locations.

Practical surfaces and coatings naturally show contact angle hysteresis, indicating a range of equilibrium values. When we measure static contact angles, we get a single value within this range. Solely relying on static measurements poses problems, like poor repeatability and incomplete surface assessment regarding adhesion, cleanliness, roughness, and homogeneity.

In practical applications, we need to understand a surface’s liquid spreading ease (advancing angle) and removal ease (receding angle), such as in painting and cleaning. Measuring advancing and receding angles offers a holistic view of liquid-solid interaction, unlike static measurements, which yield an arbitrary value within the range.

This insight is crucial for real-world surfaces with variations, roughness, and dynamics, aiding industries like cosmetics, materials science, and biotechnology in designing effective surfaces and optimizing processes.

Learn how Contact Angle measurement is done on our Tensiometer

For a more complete understanding of Contact Angle measurement, read our Contact Angle measurement: The Definitive Guide

This property measures the force that acts on the surface of a liquid, aiming to minimize its surface area.

Dynamic Surface Tension

Dynamic surface tension differs from static surface tension, which refers to the surface energy per unit area (or force acting per unit length along the edge of a liquid surface).

Static surface tension characterizes the equilibrium state of the liquid interface, while dynamic surface tension accounts for the kinetics of changes at the interface. These changes could involve the presence of surfactants, additives, or variations in temperature, pressure, and composition at the interface.

Dynamic surface tension is essential for processes that involve rapid changes at the liquid-gas or liquid-liquid interface, such as droplet and bubble formation or coalescence (change of surface area), behavior of foams, and drying of paints (change of composition, e.g., evaporation of solvent). We measure it by analyzing the shape of a hanging droplet over time.

Dynamic surface tension applies to various industries, including cosmetics, coatings, pharmaceuticals, paint, food and beverage, and industrial processes, where understanding and controlling the behavior of liquid interfaces is essential for product quality and process efficiency.

Learn how Surface Tension measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Tension measurement: The Definitive Guide

Learn how Surface Energy measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Energy measurement: The Definitive Guide

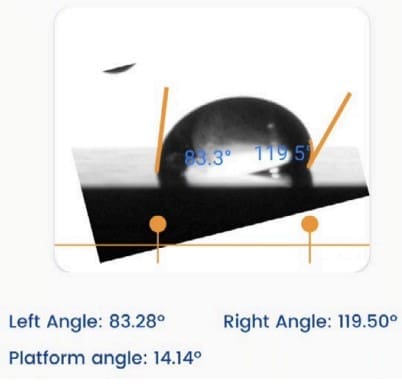

The sliding angle measures the angle at which a liquid film slides over a solid surface. It is commonly employed to assess the slip resistance of a surface.

Learn how Sliding Angle measurement is done on our Tensiometer

For a more complete understanding of Sliding Angle measurement, read our Sliding Angle Measurement: The Definitive Guide

Within the Cosmetics industry, several case studies exemplify the advantages of conducting surface property measurements.

Sunscreen does more than just block the sun—it forms a protective barrier between our delicate skin and relentless ultraviolet rays. Understanding the underlying science behind this solution has been crucial. When researchers examined contact angles between sunscreen droplets and skin, they discovered that optimizing them would provide a more uniform, reliable, resilient, and longer-lasting protective layer. This data also suggested the possibility of a sunscreen that felt less like a mask and more like a second skin—a sunscreen you could wear without feeling weighed down.

Moisturizers are key to healthy skin, but not all are created equal. That initial silky feel might seem important, but prioritizing long-lasting hydration is key to a successful moisturizer. Researchers explored the droplet contact angles and found that the moisturizer would penetrate deeper when these angles were optimized, allowing them to nourish multiple layers and not just the surface. Imagine a moisturizer that works round the clock to provide lasting, deep-rooted hydration. That’s science and innovation combined.

Everyone wants a mascara that stays put, but how do you scientifically make that possible? Researchers found the answer by exploring how mascara bonds with the skin and eyelashes. By examining the contact angles of mascara droplets, formulators identified a formula for smudge-free, long-lasting wear. With this precision, wearers can say goodbye to regular touch-ups and hello to the confidence that lasts.

The world of color cosmetics is vast and complex. Formulators realized they could bridge the gap between color, texture, and individual skin types. Cosmetic research enables products that don’t just sit on the skin but become a part of it, or at least take on that appearance.

Precision-measured interactions mean cosmetics can adapt and respond to different skin conditions, leading to a more personalized beauty experience. This is more than an enhancement— a revolution in users’ relationship with their makeup.

The environment matters to both consumers and businesses, and sustainable cosmetics have become a necessity. Industry-wide ventures into surface science have optimized product performance and championed environmental responsibility. By understanding molecular-level interactions, researchers assist formulators in creating efficient and eco-friendly products. In a world grappling with environmental challenges, this research and insight offer a beacon of hope and a roadmap for a greener future in cosmetics.

At the heart of these tales is a common thread: the undeniable power of surface property measurements. When wielded with precision and insight, they transform challenges into success stories, ensuring that pigments do more than just color surfaces; they also interact, adhere, and last.

If you are interested in implementing these or any other applications, please contact us.

In an industry where precision reigns supreme, where do Cosmetics manufacturers turn to ensure their products can survive scrutiny? The answer lies in standards and guidelines: the compass that guides cosmetics manufacturers through the complex maze of quality and performance.

This standard focuses on preserving constant relative humidity, which is crucial when researching how cosmetics behave under various humidity levels. It may indirectly affect how different humidity levels influence the interaction between cosmetics and skin surfaces.

This ISO standard outlines good manufacturing practices for the cosmetics sector. Although it is not directly related to surface science, it is essential for ensuring the quality and safety of cosmetic products that come into contact with the skin.

This standard determines liquid strikethrough time for nonwoven fabrics, frequently used in cosmetic products like makeup removal wipes. It provides insights into how liquids interact with nonwoven materials, which is important for interactions in the cosmetics industry.

We hope this guide showed you how to apply surface science in cosmetics industry.

Now we’d like to turn it over to you:

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.