Reviewed: 28

This is a practical guide to Surface Science for researchers working in the Food & Beverages Industry.

In this all-new guide you’ll learn all about:

Let’s dive right in.

In the highly competitive domain of food and beverages, a multitude of obstacles are consistently present. Professionals in this field are always faced with intricate challenges, ranging from attaining optimal texture in sauces to guaranteeing the preservation of packaged products.

The significance of surface qualities is sometimes underestimated in the art of food creation. Surface Science measurements have an impact on several aspects ranging from the texture of chocolate to the longevity of drinks on store shelves. By acquiring a more profound comprehension of these aspects, one might potentially transform their approach to food and beverage manufacturing, resulting in exceptional levels of quality and flavor.

We use the important surface properties below to understand the behavior of Food & Beverages products and improve their quality.

Young – Laplace Method

Polynomial Method

Dynamic Contact Angle

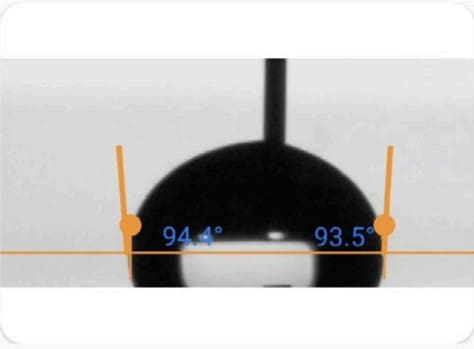

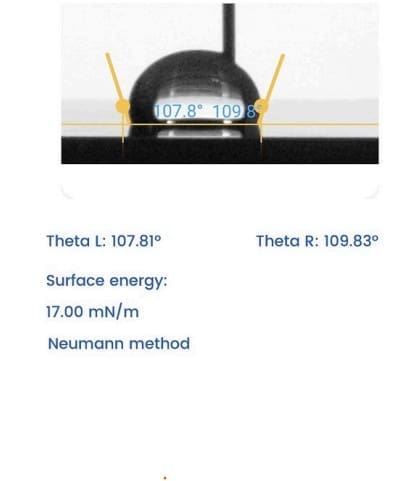

Ideally, when we place a drop on a solid surface, a unique angle exists between the liquid and the solid surface. We can calculate the value of this ideal contact angle (the so-called Young’s contact angle) using Young’s equation. In practice, due to surface geometry, roughness, heterogeneity, contamination, and deformation, the contact angle value on a surface is not necessarily unique but falls within a range. We call this range’s upper and lower limits the advancing contact angle and the receding contact angle, respectively. The values of advancing and receding contact angles for a solid surface are also very sensitive. They can be affected by many parameters, such as temperature, humidity, homogeneity, and minute contamination of the surface and liquid. For example, the advancing and receding contact angles of a surface can differ at different locations.

Practical surfaces and coatings naturally show contact angle hysteresis, indicating a range of equilibrium values. When we measure static contact angles, we get a single value within this range. Solely relying on static measurements poses problems, like poor repeatability and incomplete surface assessment regarding adhesion, cleanliness, roughness, and homogeneity.

In practical applications, we need to understand a surface’s liquid spreading ease (advancing angle) and removal ease (receding angle), such as in painting and cleaning. Measuring advancing and receding angles offers a holistic view of liquid-solid interaction, unlike static measurements, which yield an arbitrary value within the range.

This insight is crucial for real-world surfaces with variations, roughness, and dynamics, aiding industries like cosmetics, materials science, and biotechnology in designing effective surfaces and optimizing processes.

Learn how Contact Angle measurement is done on our Tensiometer

For a more complete understanding of Contact Angle measurement, read our Contact Angle measurement: The Definitive Guide

This property measures the force that acts on the surface of a liquid, aiming to minimize its surface area.

Dynamic Surface Tension

Dynamic surface tension differs from static surface tension, which refers to the surface energy per unit area (or force acting per unit length along the edge of a liquid surface).

Static surface tension characterizes the equilibrium state of the liquid interface, while dynamic surface tension accounts for the kinetics of changes at the interface. These changes could involve the presence of surfactants, additives, or variations in temperature, pressure, and composition at the interface.

Dynamic surface tension is essential for processes that involve rapid changes at the liquid-gas or liquid-liquid interface, such as droplet and bubble formation or coalescence (change of surface area), behavior of foams, and drying of paints (change of composition, e.g., evaporation of solvent). We measure it by analyzing the shape of a hanging droplet over time.

Dynamic surface tension applies to various industries, including cosmetics, coatings, pharmaceuticals, paint, food and beverage, and industrial processes, where understanding and controlling the behavior of liquid interfaces is essential for product quality and process efficiency.

Learn how Surface Tension measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Tension measurement: The Definitive Guide

Learn how Surface Energy measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Energy measurement: The Definitive Guide

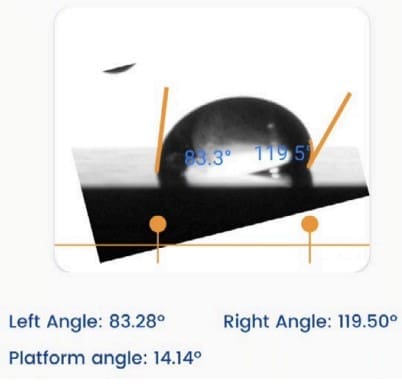

The sliding angle measures the angle at which a liquid film slides over a solid surface. It is commonly employed to assess the slip resistance of a surface.

Learn how Sliding Angle measurement is done on our Tensiometer

For a more complete understanding of Sliding Angle measurement, read our Sliding Angle Measurement: The Definitive Guide

Within the Food & Beverages industry, several case studies exemplify the advantages of conducting surface property measurements.

Imagine you’re a chocolatier, striving to create chocolates that not only taste exquisite but also have a captivating aesthetic. The technique of chocolate tempering is crucial for achieving the desired texture and glossy appearance. Traditionally, tempering requires precise temperature control, but surface science measurements simplify this process significantly.

By accurately measuring surface tension and surface energy, you can attain the optimal temper for chocolates. Manipulating these surface properties ensures your chocolates have a rich, pleasing texture and an appealing, shiny appearance that attracts consumers. Say goodbye to the inconsistencies of traditional tempering methods and embrace a more reliable and efficient approach that elevates the quality of your chocolate creations to new heights.

In the beverage industry, maintaining freshness is paramount. For manufacturers of juices, soft drinks, and alcoholic beverages, ensuring product freshness and shelf life is crucial. Conventional packaging techniques often fall short, leading to wasted resources and increased costs.

Accurate contact angle measurement provides a critical evaluation of the wetting characteristics of beverage packaging materials. This knowledge allows you to select materials that effectively prevent moisture infiltration, thereby prolonging the quality and shelf life of your drinks. This practice not only reduces product waste but also lowers packaging costs, ultimately enhancing the financial performance of the organization.

If you are interested in implementing these or any other applications, please contact us.

In an industry where precision reigns supreme, where do Food & Beverages manufacturers turn to ensure their products can survive scrutiny? The answer lies in standards and guidelines: the compass that guides cosmetics manufacturers through the complex maze of quality and performance.

This standard offers key standards for assessing how packaging affects product quality and safety during storage. This standard helps producers and regulators guarantee packaging protects product freshness, flavor, and safety via rigorous testing. It boosts customer trust and encourages food and beverage packaging improvement.

The ASTM E1871-17 provides basic parameters for uniform and standardized food and beverage sensory evaluations. This standard offers explicit processes for choosing, preparing, and serving sensory panelists samples, providing accurate and repeatable results. By adopting ASTM E1871-17, professionals may make educated product development, quality improvement, and customer preference choices, resulting in more attractive food and beverage goods.

We hope this guide showed you how to apply surface science in cosmetics industry.

Now we’d like to turn it over to you:

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.

One Response

Helpful post, especially for beginners like me.