Reviewed: 28

This is a practical guide to Surface Science for researchers working in the Telecommunications Industry.

In this all-new guide you’ll learn all about:

Let’s dive right in.

In today’s world, telecommunications system can be characterized by voice, data, and video networks. This sector is continuously enabling global connectivity, facilitating information exchange, and driving economic growth. Extending the life of crucial components like outdoor antennas and safeguarding cables from environmental damage are some major challenges faced by this sector. And in this regard surface properties, which plays crucial role in the interaction between different materials and their surroundings, becomes very important.

We use the important surface properties below to understand the behavior of Telecommunications products and improve their quality.

Young – Laplace Method

Polynomial Method

Dynamic Contact Angle

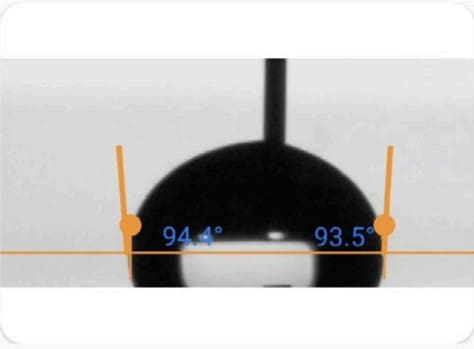

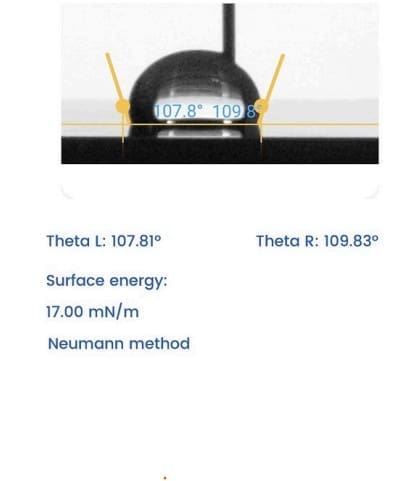

Ideally, when we place a drop on a solid surface, a unique angle exists between the liquid and the solid surface. We can calculate the value of this ideal contact angle (the so-called Young’s contact angle) using Young’s equation. In practice, due to surface geometry, roughness, heterogeneity, contamination, and deformation, the contact angle value on a surface is not necessarily unique but falls within a range. We call this range’s upper and lower limits the advancing contact angle and the receding contact angle, respectively. The values of advancing and receding contact angles for a solid surface are also very sensitive. They can be affected by many parameters, such as temperature, humidity, homogeneity, and minute contamination of the surface and liquid. For example, the advancing and receding contact angles of a surface can differ at different locations.

Practical surfaces and coatings naturally show contact angle hysteresis, indicating a range of equilibrium values. When we measure static contact angles, we get a single value within this range. Solely relying on static measurements poses problems, like poor repeatability and incomplete surface assessment regarding adhesion, cleanliness, roughness, and homogeneity.

In practical applications, we need to understand a surface’s liquid spreading ease (advancing angle) and removal ease (receding angle), such as in painting and cleaning. Measuring advancing and receding angles offers a holistic view of liquid-solid interaction, unlike static measurements, which yield an arbitrary value within the range.

This insight is crucial for real-world surfaces with variations, roughness, and dynamics, aiding industries like cosmetics, materials science, and biotechnology in designing effective surfaces and optimizing processes.

Learn how Contact Angle measurement is done on our Tensiometer

For a more complete understanding of Contact Angle measurement, read our Contact Angle measurement: The Definitive Guide

This property measures the force that acts on the surface of a liquid, aiming to minimize its surface area.

Dynamic Surface Tension

Dynamic surface tension differs from static surface tension, which refers to the surface energy per unit area (or force acting per unit length along the edge of a liquid surface).

Static surface tension characterizes the equilibrium state of the liquid interface, while dynamic surface tension accounts for the kinetics of changes at the interface. These changes could involve the presence of surfactants, additives, or variations in temperature, pressure, and composition at the interface.

Dynamic surface tension is essential for processes that involve rapid changes at the liquid-gas or liquid-liquid interface, such as droplet and bubble formation or coalescence (change of surface area), behavior of foams, and drying of paints (change of composition, e.g., evaporation of solvent). We measure it by analyzing the shape of a hanging droplet over time.

Dynamic surface tension applies to various industries, including cosmetics, coatings, pharmaceuticals, paint, food and beverage, and industrial processes, where understanding and controlling the behavior of liquid interfaces is essential for product quality and process efficiency.

Learn how Surface Tension measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Tension measurement: The Definitive Guide

Learn how Surface Energy measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Energy measurement: The Definitive Guide

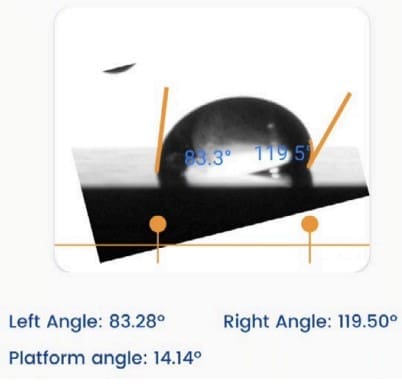

The sliding angle measures the angle at which a liquid film slides over a solid surface. It is commonly employed to assess the slip resistance of a surface.

Learn how Sliding Angle measurement is done on our Tensiometer

For a more complete understanding of Sliding Angle measurement, read our Sliding Angle Measurement: The Definitive Guide

Within the Telecommunications industry, several case studies exemplify the advantages of conducting surface property measurements.

Challenge: Telecom companies face challenges with signal attenuation during heavy rain (rain fade) and disruptions due to ice and snow accumulation on infrastructure like antennas and satellite dishes. These issues can severely impact signal transmission reliability.

Solution: The company aimed to enhance 5G antenna performance under rainy conditions by developing superhydrophobic coatings. Through rigorous experiments with different coatings, they optimized contact angles to design surfaces with high water repellency. This innovation significantly reduced rain attenuation by preventing water droplets from interfering with signal transmission. As a result, the antennas maintained strong signal strengths even during heavy rain.

Moreover, in cold regions prone to ice and snow buildup on satellite dishes, the company conducted tests to identify superhydrophobic materials with large contact angles and low sliding angles. These materials effectively minimized ice adhesion, ensuring uninterrupted signal reception. By reducing the accumulation of ice on the dishes, they enhanced operational reliability and maintained consistent signal transmission in extreme weather conditions.

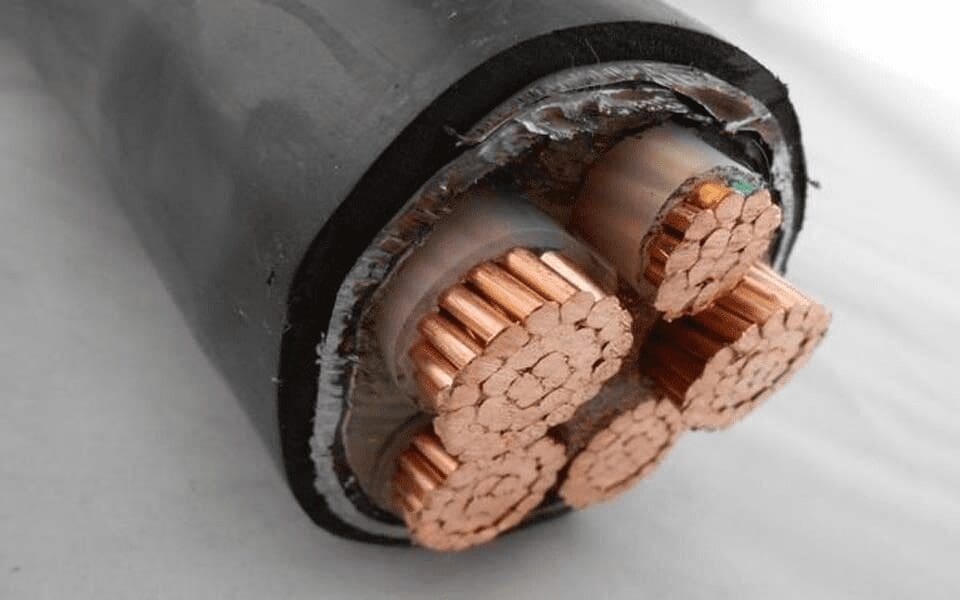

Challenge: Water ingress into cables affects signal transmission.

Solution: Optimizing the surface tension values can prevent water ingress into cables. Lowering surface tension enhances the water-repellent properties of cable insulation. A telecommunications cable manufacturer develops cables with insulation materials specially designed with low surface tension. This kind of modification will improve water resistance which will reduce the risk of signal degradation in humid environments and ensure the long-term reliability of the communication infrastructure.

Challenge: Telecom infrastructure, particularly ground-based equipment cabinets, often face issues with soil and mud adhesion. This accumulation not only affects the aesthetics but also impacts the performance and maintenance of telecom components.

Solution: To prevent soil adhesion on telecom infrastructure, the researchers measure and optimize the sliding angle of equipment cabinet surfaces. By selecting materials or applying coatings that achieve a lower sliding angle, they reduce the tendency of soil and mud to adhere to the surfaces. This innovation facilitates easier cleaning and maintenance of the cabinets, ensuring that telecom equipment remains free from environmental contaminants.

If you are interested in implementing these or any other applications, please contact us.

In an industry where precision reigns supreme, where do Telecommunications manufacturers turn to ensure their products can survive scrutiny? The answer lies in standards and guidelines: the compass that guides cosmetics manufacturers through the complex maze of quality and performance.

This standard provides guidelines for measuring advancing contact angles, which is important for evaluating surface wettability and adhesion characteristics of coatings and materials used in telecom equipment.

This ISO standard specifies a method for measuring the contact angle of liquids on solid surfaces using axisymmetric drop shape analysis. It is applicable to evaluating the surface properties of materials used in telecom equipment.

We hope this guide showed you how to apply surface science in cosmetics industry.

Now we’d like to turn it over to you:

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.