Reviewed: 28

This is a practical guide to Surface Science for researchers working in the Transportation Industry.

In this all-new guide you’ll learn all about:

Let’s dive right in.

The transportation industry boasts a diverse range of service providers, encompassing air, road, rail, and sea transport. It extends beyond just movement, also including warehousing, handling, stevedoring, and value-added services like packaging, labeling, and assembly. Optimizing surface characteristics according to the specific needs of each service plays a crucial role in all these areas, ultimately enhancing overall efficiency.

We use the important surface properties below to understand the behavior of Transportation products and improve their quality.

Young – Laplace Method

Polynomial Method

Dynamic Contact Angle

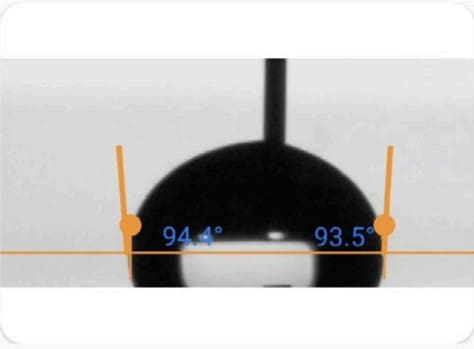

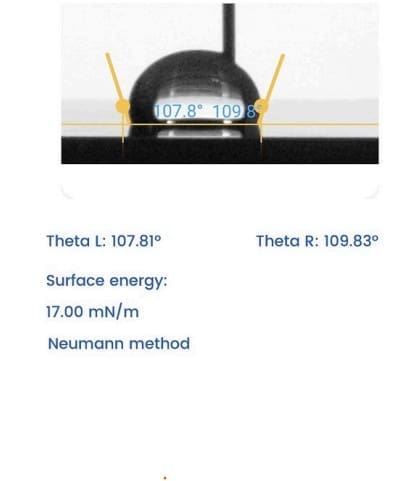

Ideally, when we place a drop on a solid surface, a unique angle exists between the liquid and the solid surface. We can calculate the value of this ideal contact angle (the so-called Young’s contact angle) using Young’s equation. In practice, due to surface geometry, roughness, heterogeneity, contamination, and deformation, the contact angle value on a surface is not necessarily unique but falls within a range. We call this range’s upper and lower limits the advancing contact angle and the receding contact angle, respectively. The values of advancing and receding contact angles for a solid surface are also very sensitive. They can be affected by many parameters, such as temperature, humidity, homogeneity, and minute contamination of the surface and liquid. For example, the advancing and receding contact angles of a surface can differ at different locations.

Practical surfaces and coatings naturally show contact angle hysteresis, indicating a range of equilibrium values. When we measure static contact angles, we get a single value within this range. Solely relying on static measurements poses problems, like poor repeatability and incomplete surface assessment regarding adhesion, cleanliness, roughness, and homogeneity.

In practical applications, we need to understand a surface’s liquid spreading ease (advancing angle) and removal ease (receding angle), such as in painting and cleaning. Measuring advancing and receding angles offers a holistic view of liquid-solid interaction, unlike static measurements, which yield an arbitrary value within the range.

This insight is crucial for real-world surfaces with variations, roughness, and dynamics, aiding industries like cosmetics, materials science, and biotechnology in designing effective surfaces and optimizing processes.

Learn how Contact Angle measurement is done on our Tensiometer

For a more complete understanding of Contact Angle measurement, read our Contact Angle measurement: The Definitive Guide

This property measures the force that acts on the surface of a liquid, aiming to minimize its surface area.

Dynamic Surface Tension

Dynamic surface tension differs from static surface tension, which refers to the surface energy per unit area (or force acting per unit length along the edge of a liquid surface).

Static surface tension characterizes the equilibrium state of the liquid interface, while dynamic surface tension accounts for the kinetics of changes at the interface. These changes could involve the presence of surfactants, additives, or variations in temperature, pressure, and composition at the interface.

Dynamic surface tension is essential for processes that involve rapid changes at the liquid-gas or liquid-liquid interface, such as droplet and bubble formation or coalescence (change of surface area), behavior of foams, and drying of paints (change of composition, e.g., evaporation of solvent). We measure it by analyzing the shape of a hanging droplet over time.

Dynamic surface tension applies to various industries, including cosmetics, coatings, pharmaceuticals, paint, food and beverage, and industrial processes, where understanding and controlling the behavior of liquid interfaces is essential for product quality and process efficiency.

Learn how Surface Tension measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Tension measurement: The Definitive Guide

Learn how Surface Energy measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Energy measurement: The Definitive Guide

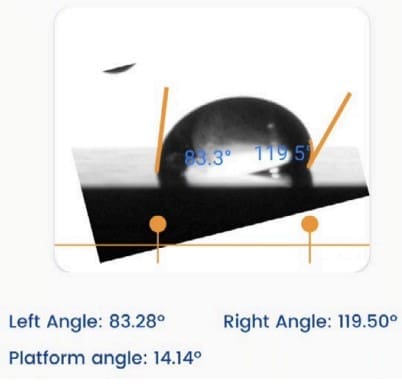

The sliding angle measures the angle at which a liquid film slides over a solid surface. It is commonly employed to assess the slip resistance of a surface.

Learn how Sliding Angle measurement is done on our Tensiometer

For a more complete understanding of Sliding Angle measurement, read our Sliding Angle Measurement: The Definitive Guide

Within the Transportation industry, several case studies exemplify the advantages of conducting surface property measurements.

To combat the dangerous threat of ice buildup on aircraft wings, coatings are being developed with a dual purpose: anti-icing and de-icing. These coatings must effectively repel water droplets, prevent ice formation from both vapor and liquid states, and most importantly, significantly reduce ice adhesion once it forms. Measuring the contact angle and sliding angle becomes crucial in evaluating the effectiveness of superhydrophobic coatings for de-icing. By designing ice-phobic coatings with a low sliding angle, we can prevent ice from sticking and facilitate its easy removal, ultimately saving time and resources during deicing procedures.

Despite their excellent mechanical and thermal properties, titanium alloys used in aerospace and automotive transportation suffer from low adhesion and corrosion. To address this challenge, we can create low-wetting surfaces on the alloy substrate. Anodization, for example, can be used on Ti6Al4V alloy to achieve a remarkable water contact angle of 158° and a sliding angle of 5.3°, creating a highly anti-adhesive surface. Alternatively, a combination of sandblasting and a hydrothermal method can be employed to prepare micro–nanoscale hierarchical structures on Ti6Al4V alloys. This method further improves the water contact angle to 161° and the sliding angle to a mere 3°, significantly enhancing the anti-adhesive properties.

If you are interested in implementing these or any other applications, please contact us.

In an industry where precision reigns supreme, where do Transportation manufacturers turn to ensure their products can survive scrutiny? The answer lies in standards and guidelines: the compass that guides cosmetics manufacturers through the complex maze of quality and performance.

This standard is valuable for evaluating surface wettability. According to this standard, a surface that readily accepts wetting is more conducive to achieving favorable coating adhesion and appearance, and less susceptible to defects associated with surface tension, such as crawling, cratering, pin-holing, and orange peel. The procedure involves measuring the contact angle when a liquid droplet is applied to a coated surface, substrate, or preformed pigment disk. Specifically focusing on advancing contact angles, this practice is designed to complement the manufacturer’s instructions for the measurement device, serving as a supplementary guide without replacing the manufacturer’s guidelines.

This testing procedure outlines the measurement of contact angles for two liquids, one polar and the other non-polar, with known surface tension. The measurements are conducted on a substrate, pigment (in disk form), or a cured/air-dried coating, enabling the calculation of the surface properties of the solid, including surface tension and its dispersion and polar components. The methodology described in this standard is grounded in the principle that the overall free energy at a surface results from the combined influences of various intermolecular forces, encompassing dispersion, polar, and hydrogen bonding.

We hope this guide showed you how to apply surface science in cosmetics industry.

Now we’d like to turn it over to you:

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.