Reviewed: 28

This is a practical guide to Surface Science for researchers working in the Utilities Industry.

In this all-new guide you’ll learn all about:

Let’s dive right in.

Energy companies, gas utilities, and transformer maintenance form the utility sector, a cornerstone of modern infrastructure crucial for our daily lives. Global demand fluctuations directly impact this sector. To meet projected demand growth, ongoing efforts are focused on upgrading electricity transmission and distribution system policies. In the utility sector, any new development must consider the critical role of surface properties. Characteristics like contact angle, sliding angle, surface tension, and surface energy play a pivotal role in ensuring the efficiency, safety, and reliability of various operations. This guide aims to shed light on the importance of these surface properties in the utility sector and showcase the potential benefits of utilizing their measurements.

We use the important surface properties below to understand the behavior of Utilities products and improve their quality.

Young – Laplace Method

Polynomial Method

Dynamic Contact Angle

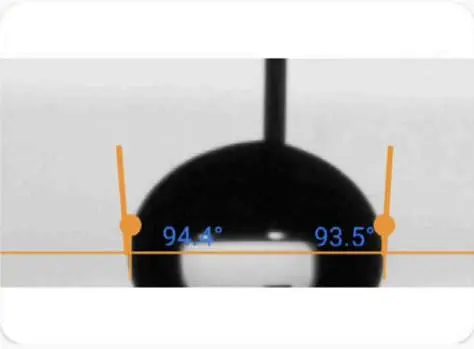

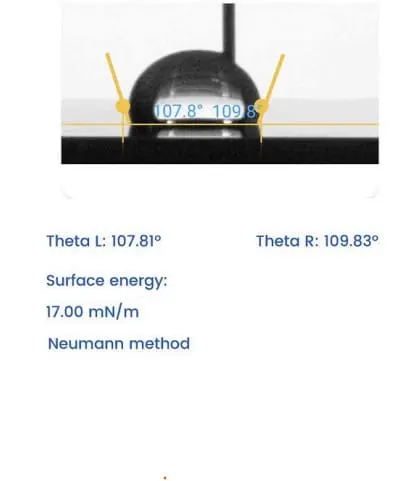

Ideally, when we place a drop on a solid surface, a unique angle exists between the liquid and the solid surface. We can calculate the value of this ideal contact angle (the so-called Young’s contact angle) using Young’s equation. In practice, due to surface geometry, roughness, heterogeneity, contamination, and deformation, the contact angle value on a surface is not necessarily unique but falls within a range. We call this range’s upper and lower limits the advancing contact angle and the receding contact angle, respectively. The values of advancing and receding contact angles for a solid surface are also very sensitive. They can be affected by many parameters, such as temperature, humidity, homogeneity, and minute contamination of the surface and liquid. For example, the advancing and receding contact angles of a surface can differ at different locations.

Practical surfaces and coatings naturally show contact angle hysteresis, indicating a range of equilibrium values. When we measure static contact angles, we get a single value within this range. Solely relying on static measurements poses problems, like poor repeatability and incomplete surface assessment regarding adhesion, cleanliness, roughness, and homogeneity.

In practical applications, we need to understand a surface’s liquid spreading ease (advancing angle) and removal ease (receding angle), such as in painting and cleaning. Measuring advancing and receding angles offers a holistic view of liquid-solid interaction, unlike static measurements, which yield an arbitrary value within the range.

This insight is crucial for real-world surfaces with variations, roughness, and dynamics, aiding industries like cosmetics, materials science, and biotechnology in designing effective surfaces and optimizing processes.

Learn how Contact Angle measurement is done on our Tensiometer

For a more complete understanding of Contact Angle measurement, read our Contact Angle measurement: The Definitive Guide

This property measures the force that acts on the surface of a liquid, aiming to minimize its surface area.

Dynamic Surface Tension

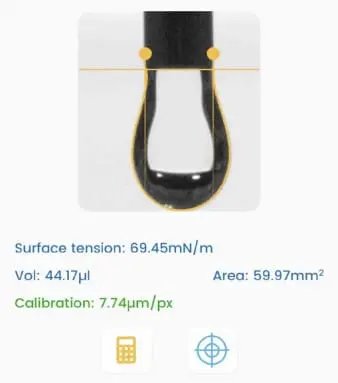

Dynamic surface tension differs from static surface tension, which refers to the surface energy per unit area (or force acting per unit length along the edge of a liquid surface).

Static surface tension characterizes the equilibrium state of the liquid interface, while dynamic surface tension accounts for the kinetics of changes at the interface. These changes could involve the presence of surfactants, additives, or variations in temperature, pressure, and composition at the interface.

Dynamic surface tension is essential for processes that involve rapid changes at the liquid-gas or liquid-liquid interface, such as droplet and bubble formation or coalescence (change of surface area), behavior of foams, and drying of paints (change of composition, e.g., evaporation of solvent). We measure it by analyzing the shape of a hanging droplet over time.

Dynamic surface tension applies to various industries, including cosmetics, coatings, pharmaceuticals, paint, food and beverage, and industrial processes, where understanding and controlling the behavior of liquid interfaces is essential for product quality and process efficiency.

Learn how Surface Tension measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Tension measurement: The Definitive Guide

Learn how Surface Energy measurement is done on our Tensiometer

For a more complete understanding of Surface Energy measurement, read our Surface Energy measurement: The Definitive Guide

The sliding angle measures the angle at which a liquid film slides over a solid surface. It is commonly employed to assess the slip resistance of a surface.

Learn how Sliding Angle measurement is done on our Tensiometer

For a more complete understanding of Sliding Angle measurement, read our Sliding Angle Measurement: The Definitive Guide

Within the Utilities industry, several case studies exemplify the advantages of conducting surface property measurements.

Offshore equipment faces a harsh reality: constant exposure to saltwater leads to corrosion and decreased lifespan. The Company’s maintenance team combats this challenge by applying hydrophobic coatings with high contact angles directly onto equipment surfaces like pipelines, valves, and metal structures. These coatings actively repel water, preventing the formation of corrosive layers. This proactive approach extends the critical infrastructure’s lifespan, ultimately reducing maintenance costs and boosting the overall efficiency of offshore operations.

Natural gas processing facilities face the challenge of preventing fire-related accidents through stringent safety measures. The solution lies in recognizing the crucial role surface properties of coated equipment play in fire prevention and damage minimization. Plants can introduce flame-retardant coatings with low surface energy on various structural components and equipment surfaces. These coatings effectively reduce surface tension, making it difficult for flammable materials to adhere to surfaces.

Oil leakage from transformers can severely degrade the performance of room temperature vulcanized (RTV) silicone rubber coatings. To investigate this, we can utilize contact angle measurements to assess the impact of transformer oil on RTV silicone rubber performance. Previous studies indicate that contact angle initially increases with short immersion times but then fluctuates as immersion duration lengthens. Despite these fluctuations, all samples maintain good hydrophobicity. In this study, we immersed RTV silicone rubber in transformer oil for varying periods. This demonstrates the potential of contact angle measurements to effectively investigate the degradation of RTV silicone rubber caused by transformer oil.

Aging transformers face the challenge of insulation failure, which can have severe consequences for both safety and economic impact if not identified and addressed quickly. Scheduled maintenance practices employ various laboratory techniques as solutions for aging detection. These methods include breakdown voltage (BDV), spectroscopy, dissolved gas analysis, total acid number, and interfacial tension. A previous study suggests that interfacial tension (IFT) and total acid number (TAN) are more accurate reflections of transformer oil aging compared to other techniques, which can be influenced by unrelated parameters. Since assessing interfacial tension involves evaluating the oil’s surface tension, evaluating surface properties becomes crucial in studying aging-related insulation failure in transformers.

Challenge: Oil production faces a significant hurdle in managing corrosion during multiphase flow.

Solution: This multiphase flow refers specifically to oil-water-gas mixtures flowing through steel pipes. Previous research suggests that pre-adsorption of inhibitor molecules onto the steel surface can potentially alter its wettability, shifting it from water-loving (hydrophilic) to oil-loving (hydrophobic). This change in surface behavior could ultimately lead to reduced corrosion by promoting oil wetting. Measuring contact angle and surface tension plays a crucial role in understanding and quantifying this conversion from hydrophilic to hydrophobic states.

If you are interested in implementing these or any other applications, please contact us.

In an industry where precision reigns supreme, where do Utilities manufacturers turn to ensure their products can survive scrutiny? The answer lies in standards and guidelines: the compass that guides cosmetics manufacturers through the complex maze of quality and performance.

This standard encompasses fresh mineral insulating oil derived from petroleum, designed to serve as an insulating and cooling agent in both new and already deployed power and distribution electrical equipment. This equipment includes transformers, regulators, reactors, circuit breakers, switchgear, and associated devices.

This standard defines a test method for determining the surface free energy of a solid surface by measuring the contact angle. The method is applicable to characterize both substrates and coatings.

This standard outlines a testing procedure for quantifying the surface tension of liquids through an optical method involving the pendant drop. This method is suitable for evaluating liquid coating materials. However, its applicability may be limited to liquids exhibiting non-Newtonian rheology.

This standard outlines a test method for optical determination of the polar and dispersive fractions of liquid surface tension. It is suitable for characterizing liquid coating materials, but its applicability may be limited to liquids exhibiting non-Newtonian rheology.

We hope this guide showed you how to apply surface science in cosmetics industry.

Now we’d like to turn it over to you:

Droplet Lab was founded in 2016 by Dr. Alidad Amirfazli, faculty member at York University, and two of his researchers, Dr. Huanchen Chen and Dr. Jesus L. Muros-Cobos.

Dropletlab © 2024 All Rights Reserved.